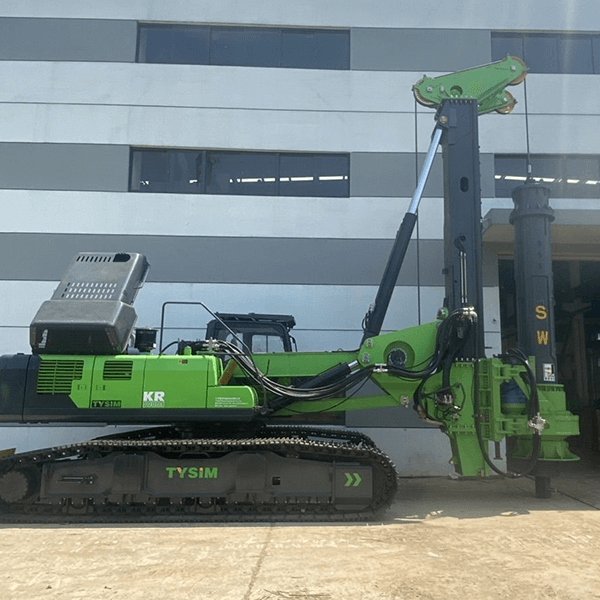

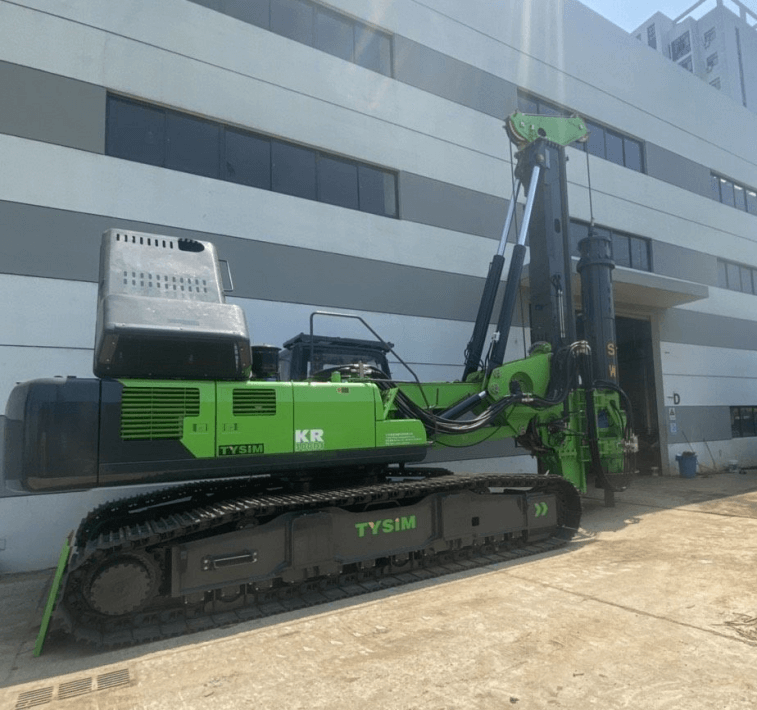

LOW HEADROOM DRILLNG RIGS(LHR)KR300ES

LHR KR300ES has many excellent features that set it apart from traditional drilling rigs. Its main advantage is its low headroom design for optimal operation in limited clearance areas. Compact and agile, the rig can be easily maneuvered in the most challenging environments, providing unrivaled versatility and efficiency.

Equipped with the latest technology, the LHR KR300ES provides excellent performance in various drilling applications. Whether you need to drill for geotechnical investigations, well installation or other specialty projects, this rig delivers unmatched precision and accuracy. By selecting from a variety of drilling modes, operators can adapt the rig to different soil conditions, ensuring the best results every time.

Technical Specification

|

Technical specification of KR300DS rotary drilling rig |

||

|

Torque |

320 kN.m |

|

|

Max. diameter |

2000mm |

|

|

Max. drilling depth |

26 |

|

| Speed of rotation | 6~26 rpm | |

|

Max. crowd pressure |

220 kN |

|

|

Max. crowd pull |

230 kN |

|

|

Main winch line pull |

230 kN |

|

|

Main winch line speed |

80 m/min |

|

|

Auxiliary winch line pull |

110 kN |

|

|

Auxiliary winch line speed |

75 m/min | |

|

Stroke(crowd system) |

2000 mm |

|

|

Mast inclination(lateral) |

±5° |

|

|

Mast inclination(forward) |

5° |

|

|

Max. operating pressure |

35MPa |

|

|

Pilot pressure |

3.9 MPa |

|

|

Travel speed |

1.5 km/h | |

|

Traction force |

550 kN |

|

|

Operating height |

11087 mm |

|

|

Operating width |

4300 mm |

|

|

Transport height |

3590 mm |

|

|

Transport width |

3000 mm |

|

|

Transport length |

10651 mm | |

|

Overall weight |

76t |

|

|

Engine |

||

|

Model |

Cummins QSM11 |

|

|

Cylinder number*diameter*stroke(mm) |

6*125*147 |

|

|

Displacement(L) |

10.8 |

|

|

Rated power(kW/rpm) |

280/2000 |

|

|

Output standard |

European III |

|

|

Kelly bar |

||

|

Type |

Interlocking |

|

|

Section*length |

7*5000(standard) |

|

|

Depth |

26m |

|

Product Details

POWER

These drilling rigs have large engine and hydraulic capacities. This translates into the rigs being able to use far more powerful winches for the Kelly bar, crowd, and pullback, as well as faster rpm at higher torque when drilling with casing in overburden. The beefed up structure can also support the additional stresses put on the rig with stronger winches.

DESIGN

Numerous design features result in less downtime and longer equipment life.

The rigs are based on reinforced CAT carriers so spare parts are easy to obtain.

Construction photos

Product packaging